Optimize Decarbonization through Retrofit

How a focus on existing building stock can meet carbon reduction goals

A focus on retrofitting buildings will help meet carbon reduction goals, said Stephen Selkowitz, principal, Stephen Selkowitz Consultants, during his presentation, “The Last Single-Glazed Building—Options to Update U.S. Buildings with High-Performance Windows,” at the NGA Glass Conference: Isle of Palms in February 2024.

The United Nations’ Global Roadmap outlines how the world can achieve net-zero emissions by 2050. U.S. President Joe Biden signed an executive order in 2021 to make the federal government carbon-neutral by 2050, aiming for a 65% reduction in greenhouse gas emissions by 2030. These lofty goals require big thinking, says Selkowitz.

Many fossil fuels are converted into electricity. Because 75% of electricity goes into buildings, says Selkowitz, buildings are right up there with transportation in terms of carbon emitters. Building envelopes are a huge opportunity to reduce electricity, thereby reducing carbon emissions.

Selkowitz also differentiated between energy use and carbon emissions. A building can use a lot of energy, he says, but if it comes from zero carbon electricity, they’re not using much carbon.

Existing building stock

“Although we should pay attention to new construction, we have to look at retrofit and renovation,” Selkowitz says. New construction is an estimated 1% to 2% of stock while retrofits are 2% to 4% of stock, he says. “If you don’t touch existing buildings today, you’ll never meet the 2050 goals,” Selkowitz asserts.

Buildings are durable. As such, there is still a lot of single glazing out there. According to data from 2020, 60% of U.S. window stock is single glazing. More than 50% of the buildings that will be in place in 2050 already exist, so we must address existing glazing Selkowitz says.

Drivers behind high-performance buildings include energy efficiency, demand responsiveness, resiliency, decarbonization and carbon/energy reduction. But building owners and occupants also prioritize cost, comfort, outdoor views, well-being, indoor air quality and productivity. “In the end, you won’t do anything people can’t or won’t afford,” says Selkowitz. “We must couple improvements in fenestration and glazing that give efficiency but deliver benefits.”

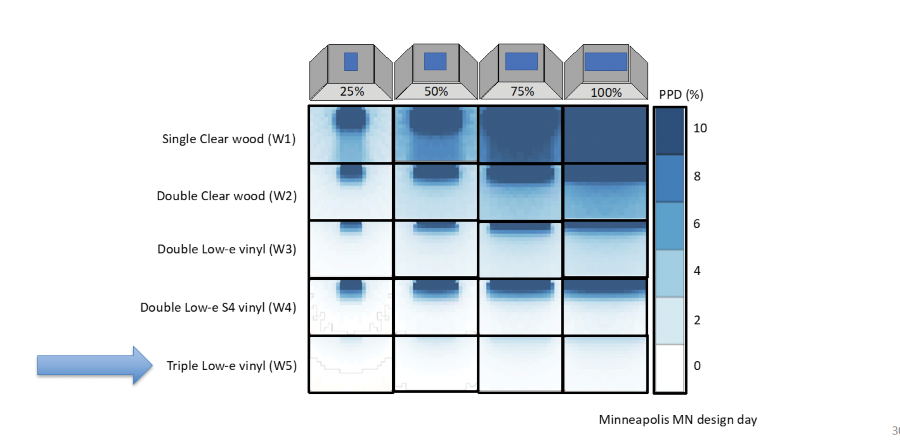

Residentially speaking, comfort perhaps is the biggest market driver for thermally improved window retrofits. Triple low-emissivity vinyl yields the highest comfort in both draft and cold radiation effects.

Market Drivers for Thermally Improved Window Retrofits

Also of note is that building elements age differently. Façades last an estimated 15 to 50 years, while HVAC systems last about 15 to 30 years. Therefore, a building can go through several HVAC systems in the span of one window life. “The building industry is attuned to looking at HVAC and lighting, but not as much at building envelope solutions,” Selkowitz says.

Although retrofitting and renovation can be complex and costly, there are bigger net savings to be had. One commercial example is the retrofit of the Empire State Building in 2013. The team removed 6,514 double-glazed windows and re-manufactured them on-site as triples. The triples reduced the HVAC loads so the HVAC could be replaced with a smaller, cheaper system. HVAC savings resulted in faster window paybacks.

What the industry can do

So, what can the glazing industry do to create pathways toward net-zero glass/windows/façades? Selkowitz outlined five points.

- Technology innovation.

- Promote affordable, scalable, market-ready solutions.

- Create jobs to develop these solutions.

- Emphasize non-energy benefits such as quality of living and workspaces.

- Have a voice in national and regional program development.

Several technology options exist, and more are on the horizon to achieve net-zero buildings. These can include façade replacement, sash replacement, glazing replacement, secondary window systems, film add-ons, shading replacement and daylighting control.

Thin glass, or skinny triples, continue to make progress. Other growing technologies include quads and vacuum-insulating glass. Aerogel continues to remain largely in the research realm.