Product | Solution by Joseph Machine

jWeld, jClean and jFlow Welding and Cleaning Solutions

Key features

- Configured to specific product and production needs

- Easy maintenance and high uptime

- Common interface and user experience

Joseph Machine’s new jWeld, jClean and jFlow product lines are designed to help North American manufacturers thrive. As the leading producer and designer of fabrication solutions for window and door vinyl extrusions, Joseph applied its “common sense” engineering philosophy to a new lineup of welding and cleaning solutions.

Joseph Machine’s new jWeld, jClean and jFlow product lines are designed to help North American manufacturers thrive. As the leading producer and designer of fabrication solutions for window and door vinyl extrusions, Joseph applied its “common sense” engineering philosophy to a new lineup of welding and cleaning solutions.

Approach

The Joseph solutions take a modular approach with the base platforms for welding and cleaning, able to be configured to your specific product and production needs. For example, the jWeld platform can easily be converted from hydro-pneumatic clamping to full servo control. The jClean platform has dedicated frame or sash solutions as well as a combo product that can accommodate frame or sash.

Solutions

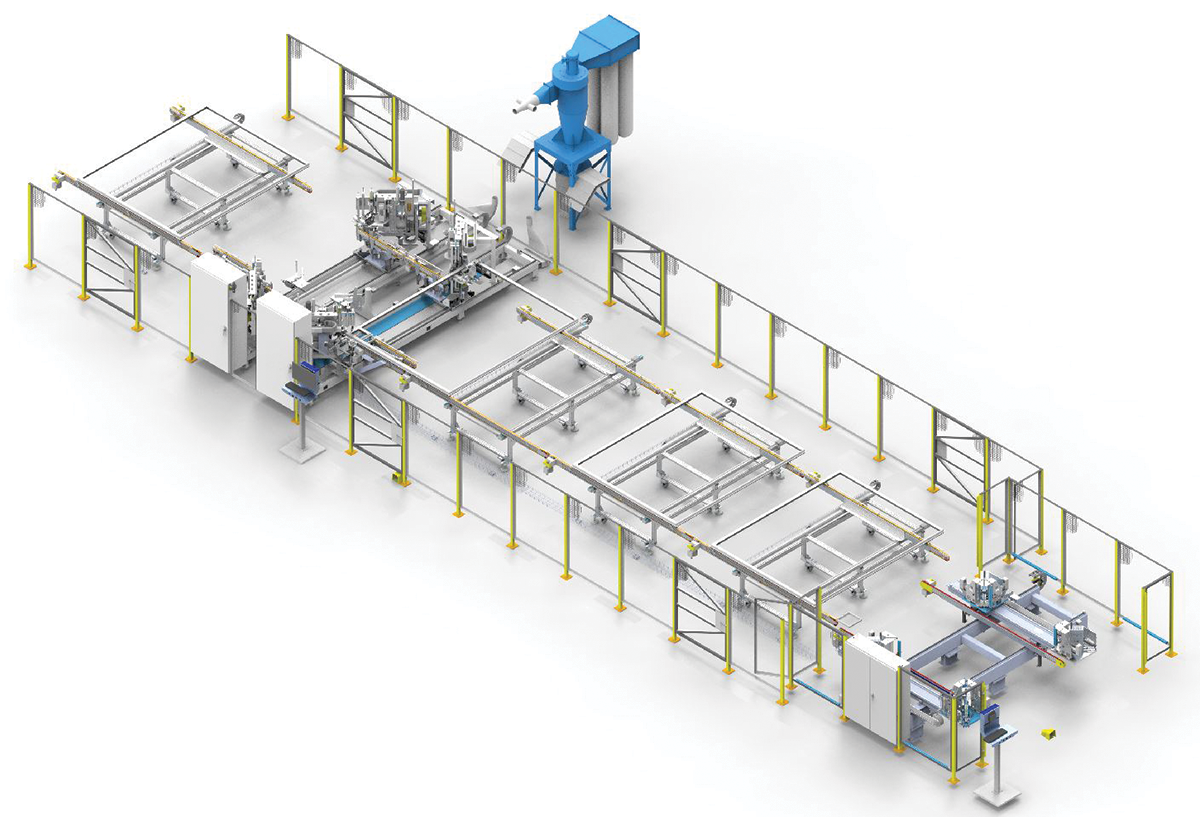

Our large installed base of fabrication centers gives us unique insight into what our customers require from an operation and maintenance standpoint for vinyl welding and cleaning. When we developed our jFlow pass-thru lines, we took into account our customers’ space constraints and issues with existing systems on the market. The result is a product that has just the right level of automation to reduce labor for welding and cleaning but also the right components and simplified engineering to allow for easy maintenance and high uptime.

Results

Our software also enables us to offer customers a common interface and user experience from “stick to opening” so that if a team member understands the logic of a fab center, interacting with a welder and a cleaner is easy and intuitive.

Learn More

For more information, visit josephmachine.com