Purposeful Automation

Define your objectives and capital expectations to automate with a plan, not just for the sake of automating

“Automation” is a buzzword we hear daily in the fenestration industry. There are various reasons for automating, including safety and ergonomics for employees, quality and consistency of product, labor shortages and costs. Many times, automation can be the answer to your production challenges.

Customers repeatedly tell us, “I want to automate everything.” This, however, may not be the best choice as you may just be adding cost and footprint to your production facility without gaining the productivity and return on investment you planned.

Before you jump into automation, clearly state your objectives and what you are trying to achieve, as well as the cost of capital considerations. You also need to ask yourself, “Why are you automating?” and, “What is the right level of automation for your business?” By focusing on these two questions, you can begin to automate with purpose.

Define your level of automation

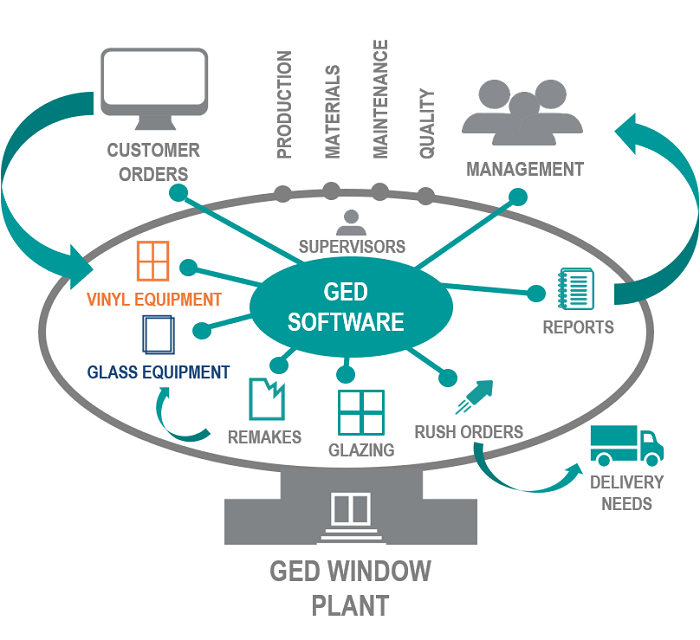

Once you have defined your objectives and capital expectations, it is time to define the level of automation. Sometimes automation is achieved simply through manufacturing execution systems (MES) software that controls the plant floor and communicates with your enterprise resource planning (ERP) system to manage and optimize processes.

Other times, automation requires more advanced systems, such as robotic implementation, that tie in multiple processes. The key is to find the crossover point where labor and software/machinery work best together. This crossover point has changed over the years as labor rates climb, automation capabilities increase and robotic costs decrease.

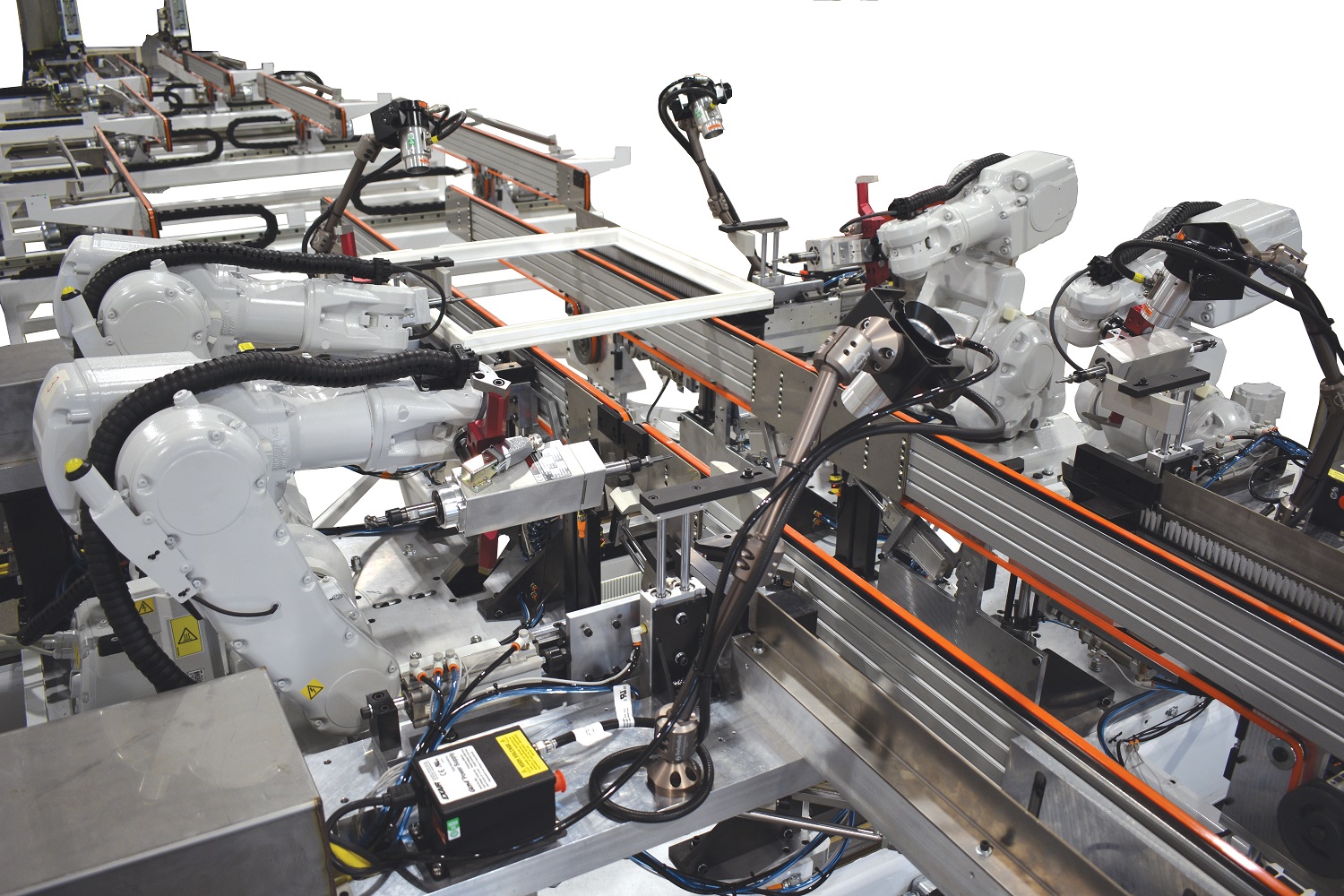

For example, many of our customers have found the benefit of using robotic automation in frame and sash processing. Historically, this is a time-consuming and labor-intensive task, but robots have challenged the status quo by improving processing, reducing labor requirements, and improving consistency and quality, while increasing productivity and speed.

To illustrate this, robots can weld up to four sashes or frames simultaneously, after which the profiles are moved on conveyors to cleaning. Four robotic cleaning heads reduce cycle times while maintaining the highest levels of precision and repeatability, and the tooling package on each robot head allows for cleaning and fabrication during the cleaning cycle. The blend of robotics and automation reduces labor, speeds up your process and improves your windows.

Robotic capability has increased dramatically throughout the decades. In 1975, robotic capability provided 5 axes of control, according to a McKinsey & Company report in 2017. Today, robots can provide 32- to 64-axis control. Additionally, robotic arms have the capability of managing over 1,000 kilograms today, whereas in 1975 their capacity was 6 kilograms.

Robots have also become more affordable with increased capabilities and flexibility. Robots take on new roles within our industry every day.

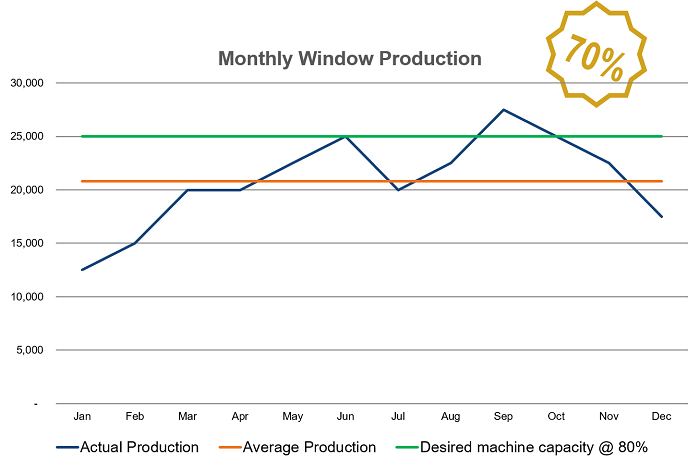

When buying equipment, make sure your equipment is not taxed to more than 70 or 75 percent of your average capacity.

Points of focus

As you build your automation plan, focus on labor vs. output vs. cost, worker safety, production adaptability and the life cycle of your product. This will help define your requirements. Although the cost of technology is becoming more affordable, you really must look at it for your shop, product, operators, operation and facility size. Your automation supplier should be able to help identify all those challenges and develop an appropriate solution.

- Labor: You must be able to get the output you require with the workers you have. Automation can help achieve greater output with fewer workers, but the type of worker may change. You may find you need a different level of worker, one with knowledge of maintaining automation systems. Be sure to identify where the crossover point is between equipment costs and labor costs.

- Safety: Worker safety is a paramount concern. Automation can help keep a worker out of the direct path of working elements of the machine and can improve ergonomics for operators. For example, a robotic arm on a cleaner can help avoid that possible operator-related injury.

- Output: Production adaptability is another consideration. It is safe to assume you do not produce the same output every day, all year long. When buying equipment, you want to make sure your equipment is not taxed to more than 70 or 75 percent of your average capacity.

- Product life cycle: Look at the stage of the life cycle of your product. If you are planning a product changeover within the year, maybe now is not the time to automate. Look at the expected growth of a given project or given product line in units per labor hour. Automation will lower your labor count, increase the footprint required for machinery and provide a consistent number of units daily, but you may introduce a constraint on your output. Make sure your units per man-hour exceed what your existing manual and semi-automated lines can achieve. Also, take into consideration your capacity for future growth and the need to service your seasonable fluctuations in demand.

Automation sometimes requires more advanced systems, such as robotic implementation, that tie in multiple processes.

Finish the plan

Now that you have defined your objectives, capital expectations, safety, the level of automation and labor, and production variables, you can finish your plan. This plan should include unique business objectives for different product lines (i.e., your high-volume lines vs. lower-volume lines). Low-volume products will not achieve the same ROI high-volume lines will provide.

Make sure you have clearly defined financial and productivity goals so you do not spin your wheels, resulting in scope creep. Stick to your plan and what you define up front. Your automation partner should be able to walk you through what you can expect and what is not feasible.

Identify what you are going to invest and what you expect to get out of it. Measure and validate your production as you implement your system. Is the ROI what you need and expect? Have you considered the intangibles and soft costs that can be hard to account for on paper, such as safety, quality and consistency? You do not want the homeowner calling your warranty department saying, “I have a problem.”

Challenge your automation supplier to help you through the process by providing you with the options to fit your production requirements and optimize the crossover point. We all must justify and rationalize everything we do, so automate when it makes sense for you based on your needs, and then right-size your level of automation. Do not just automate because you want to automate.

Top photo: The RoboFlow family of products is intended to streamline the process, from welding through cleaning. The RoboFlow PT rounds out the RoboFlow product family as a pass-through system that is designed to take cut vinyl from welding through cleaning with just one operator at faster cycle times, according to GED.