2018 International Code Requirements for Windows & Doors

Major requirements were set forth in the published 2018 I-codes for windows, doors, skylights and other fenestration products in single family homes, duplexes and townhouses that are three stories or less in height. These types of buildings are referred to as “low rise residential construction” within the family of International Codes, and requirements for them are established in the International Residential Code (IRC) and the International Energy Conservation Code (IECC).

Adoption of I-codes

The 2018 editions of the IRC and IECC are the most recent, and many states and localities are in the process of adopting this edition of I-codes. Manufacturers and dealers that sell products in several states should be aware that, at this time, multiple editions of the International Codes are being enforced across the country. To aid in this, the International Code Council (ICC) website provides an adoption chart listing the latest edition being used in each state and in some cases in a local jurisdiction.

The family of International Codes published by the International Code Council is the most widely used in the history of U.S. construction codes. In addition to their widespread use throughout the 50 states and District of Columbia, they are used in the U.S Territories of Guam, Northern Mariana Islands, U.S. Virgin Islands and Puerto Rico.

Numerous federal agencies have also adopted the International Codes. Federal agencies do not “adopt” I-codes in the same manner as states and local governments do, but agencies such as the Department of Defense, Department of State, Department of Housing and Urban Development, the Veterans Administration and General Services Administration, among others, “use” the International Codes in various ways, such as requiring them when requesting bids to construct, renovate or maintain properties and facilities.

Due to the prevalent use by federal agencies, I-codes began being enforced in countries other than the U.S, including the Middle East (Abu Dhabi, Saudi Arabia and Afghanistan). This reliance on the International Codes has now spread to other countries, including Georgia (Eastern Europe), Mexico, Columbia and Honduras.

In addition, many Caribbean countries have adopted the I-codes in the wake of devastating hurricanes and the earthquakes in Haiti. The Cayman Islands, Jamaica, Trinidad and Tobago, and the aforementioned Haiti all have adopted at a minimum the IBC and IRC. The Caribbean Community and Common Market (CARICOM: 15 Carribean counties) use the IBC, IMC, IPC and IECC as base documents for that region’s regulations.

DESIGN LOADS

Provisions for design loads of all exterior cladding of residential structures—including fenestration—are set forth in Section R301 of the 2018 IRC. The design loads of concern for vertical glazing are design wind load and impact resistance. Skylights and sloped glazing are also subject to snow load and dead load.

Wind Loads

Tables R301.2(2) and R301.2(3) of the 2018 IRC give the design wind loads for glazed openings based on the design wind speed of the specific location where construction is to take place, the mean height of the building and its exposure to wind. Overall, the prescriptive provisions continue to reference the 2010 edition of American Society of Civil Engineers (ASCE) 7, Minimum Design Loads for Buildings, while those outside these provisions must be based on the 2016 edition, which was adopted as the IRC reference standard for loads.

The design wind pressure values obtained from the 2018 IRC are to be multiplied by 0.6 for the purposes of comparison to the Design Pressure rating of the fenestration product obtained by testing in accordance with the 2017 edition of AAMA/WDMA/CSA 101/I.S.2/A440 (NAFS-17).

Other changes, however, occurred between the 2010 and 2016 editions of ASCE 7 that effect design wind loads in the 2018 I-codes. In most of the central U.S., the design wind speeds were reduced from the 2010 edition of ASCE 7 to the 2016 edition. Design wind speeds are used to calculate the design wind pressures.

For vertical glazing, this reduction in design wind speed in ASCE 7-16 results in a reduction in design wind pressure. For skylights and sloped glazing, however, other factors used to calculate design wind pressure were increased. In some cases, this increase results in a higher design wind pressure.

This increase in design wind pressure also applies to other components of the roof, such as the roof covering, sheathing and framing. For this reason, the National Association of Home Builders (NAHB), Roofing Contractors of America (RCA), and other groups, lobbied to not have them brought into the 2018 IRC.

The final result is that the prescriptive provisions of the 2018 IRC remain unchanged from the 2015 IRC and will continue to be based upon the 2010 edition of ASCE 7. But, homes that are outside the scope of the prescriptive provisions of the 2018 IRC must be designed using the 2016 edition of ASCE 7. The latter will be consistent with the 2018 IBC.

It is imperative that the builder, code official, manufacturer and anyone else involved in choosing or approving the windows, doors or skylights for a particular residence be aware as to whether the 0.6 conversion factor is appropriate or not, and which set of provisions is being used to determine the design wind pressures for the home.

AAMA, the Window & Door Manufacturers Association (WDMA), Fenestration Manufacturers Association (FMA) and Doors & Access Systems Manufacturers Association International (DASMA) published a technical bulletin (TB 11-1) on this topic. This bulletin can be downloaded from the AAMA online store, aamanet.org/store.

Dead Loads

The provisions for dead loads in Section R301.1 of the 2018 IRC are also based on ASCE 7-10; there are no significant changes to the dead load requirements for fenestration in the 2018 edition of the IRC.

Impact Resistance

Section R301.2.1.2 of the 2018 IRC outlines the locations where impact-resistant products are required. Basically, all exterior openings in wind-borne debris areas are required to be impact-resistant.

The ASCE 7-16 wind speed maps were not adopted into the 2018 code. Therefore, for those homes that fall within the scope of the prescriptive provisions of the 2018 IRC, the geographical locations where impact protection of openings is required are similar to those given in ASCE 7-10 and are primarily defined by design wind speed. For those homes outside the scope of the prescriptive provisions of the 2018 IRC, these locations will be determined in accordance with ASCE 7-16.

Products that need to meet impact resistance requirements must be tested to one of a few different sets of standards. One option is testing in accordance with ASTM E1886-13a and ASTM E1996-2014a, which must be used together.

The 2018 IRC also recognizes the AAMA 506 certification label tab as evidence that a product has been tested appropriately (see section R609.6.1). This tab provides a method for a window manufacturer to demonstrate its product has been successfully tested in accordance with ASTM E1886 and ASTM E1996 by including the tab as part of its NAFS air-water-structural certification label. The 2018 IRC also permits the use of “other approved tests.” This may include Miami-Dade County test protocols, if approved by the authority having jurisdiction.

The use of protective wood panels as an alternative to impact-resistant glazing or shutters continues to be permitted for one- and two-story, single-family dwellings, duplexes and residential care facilities.

Emergency Escape and Rescue Openings

The 2018 IRC requires emergency escape and rescue openings (EEROs) in all sleeping rooms and in all basements with two exceptions:

- Basements that are less than 200 square feet in area and used only to house mechanical equipment.

- Sleeping rooms in basements of homes that are equipped throughout with a residential sprinkler system that complies with NFPA 13R or 13D, when at least one EERO and one means of egress door, or two EEROs, are provided from the basement.

The requirements for sizes, locations, etc. are set forth in Section R310 of the 2018 IRC. It is important to note that the required opening size of 24 inches high, 20 inches wide and 5.0 or 5.7 square feet in area must be met by “normal” operation of the window, door or skylight without the use of keys, tools or special knowledge, and without the removal of a second sash from the opening.

Typically, the EERO requirements are met with operable windows or doors. Operable skylights and roof windows are also permitted to be used as EEROs if they meet the size requirements and the bottom of the opening is within 44 inches of the floor below.

Minimum Window Sill Heights

The 2018 IRC continues to require the bottom of openings created by operable windows to be a minimum height of 24 inches above the adjacent interior floor when they are more than 6 feet above the grade outside the window.

An exception from this requirement also remains in the 2018 IRC, for windows that do not open more than 4 inches or that are equipped with window guards or window opening control devices (WOCDs) that comply with ASTM F2090-17. The WOCD must limit the initial opening of the window to no more than 4 inches, but mustalsobe releasable with no more than 15 pounds of force to open more fully with two single actions or one dual action and must reset automatically once closed. The intent of this later provision is to permit windows that are equipped with WOCDs to also be used to meet the EERO requirements of the 2018 IRC.

The only change here for the 2018 IRC is the use of the 2017 edition rather than the 2010 edition of the ASTM F2090.

INSTALLATION

Window Installation

Flashing requirements found in Section R703.4 did not change in the 2018 IRC; however, the editions referencing some AAMA standards for flashing were updated. Section R703.4 of the 2018 IRC requires self-adhered membranes used as flashing to comply with AAMA 711-13 and fluid-applied flashing to comply with AAMA 714-15. Item 1 of Section R703.4 requires mechanically applied flashing to comply with AAMA 712-14.

Safety Glazing

Section R308.4 of the IRC establishes the locations where safety glazing is required. The 2018 IRC glazing requirements remain mostly unchanged, but for modifications addressing glazing adjacent to doors, in guards and railings, and adjacent to the bottom stair landing. The 2018 IRC requires glazing within 24 inches of the hinge side of an in-swinging door now have safety glazing where the glazing is at an angle less than 180 degrees from the plane of the door.

Both referenced standards used were also updated. The Consumer Product Safety Commission (CPSC) 16 CFR 1201 edition is now from 2002 (previously 1977) and the ANSI Z97.1 is the 2014 edition.

Mullions

Unchanged from the last code cycle, the 2018 IRC requires testing or structural calculations to demonstrate the ability of window mullions to meet certain structural requirements. If structural calculations are used to determine adequacy, the mullion deflection is limited to L/175 of the length of the long edge of the glass being supported.

If testing is the method used to determine structural adequacy of mullions, it is to be done in accordance with AAMA 450-10, Voluntary Performance Rating Method for Mulled Fenestration Assemblies. When the mullion is tested in accordance with AAMA 450-10, the deflection limit of L/175 does not need to be met. It should be noted that this provision is only contained in the IRC. As such, it is most commonly applied to R and LC windows and not CW or AW windows.

Site-Built Windows

The 2018 IRC requires site-built windows to be tested for design pressure in accordance with ASTM E330. This standard was updated from the 2002 edition to the 2014 edition in the 2018 IRC.

Skylights and Sloped Glazing

The 2018 IRC did not change the specific requirements for factory-built unit skylights as laid out in the previous edition but for reference to the 2017 edition of the AAMA/WDMA/CSA 101/I.S.2/A440 (NAFS-17).

ENERGY PERFORMANCE

Requirements for energy performance in both residential and commercial buildings are spelled out in the 2018 IECC. The energy conservation requirements for one- and two-family homes and townhouses three stories or less in height are also given in Chapter 11 of the 2018 IRC.

Beginning with the 2012 International Codes, the energy conservation provisions of Chapter 11 of the IRC are an exact duplicate of the provisions of the IECC for the same building. Previously, there was some variation in the energy performance requirements for residential buildings that were included in both the IECC and the IRC. In jurisdictions using the 2009 or earlier editions of these two codes, it is essential to verify which set of requirements is to be complied with before beginning a residential construction project.

The residential provisions of the 2018 IECC apply to one- and two-family homes and other types of residential construction—such as multifamily buildings and assisted-living facilities—that are three stories or less in height. For these buildings, the residential provisions of the 2018 IECC govern if it has been adopted by the Authority Having Jurisdiction. (Other types of residential occupancies, such as multifamily buildings and assisted-living facilities greater than three stories in height, and hotels and motels of any height, are governed by the provisions of the 2018 IECC for commercial buildings.)

Compliance Paths

In the 2018 IECC, there continues to be four energy conservation compliance paths for residential construction:

1. The prescriptive path,

2. The UA (area weighted average) alternate method,

3. The whole building performance path, and

4. The Energy Rating Index (ERI) path.

The prescriptive path is the simplest to use. It provides one set of energy efficiency requirements for each component of the building envelope.

Under the prescriptive path of the 2018 IECC for residential construction, there is no limit on the percentage of glazing in the exterior wall. There is also no limit on the percentage of roof area containing skylights.

The prescriptive path for residential construction establishes maximum permitted U-factor and solar heat gain coefficient (SHGC) requirements for fenestration (Table R402.1.2). U-factor is to be determined in accordance with National Fenestration Rating Council (NFRC) 100-17 or by use of a default table in the 2018 IECC. Similarly, the SHGC of the fenestration is to be determined in accordance with NFRC 200-17 or by use of a default table.

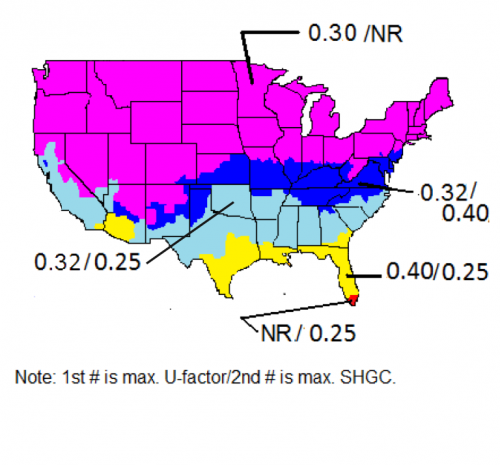

The maximum prescriptive SHGC for vertical glazing did not change between the 2015 and 2018 IECC. However, the maximum prescriptive U-factor for vertical glazing was reduced slightly in climate zones 3 through 8. In Climate Zones 3 (South Carolina to Oklahoma) and 4 (Virginia to Tennessee) it was reduced from 0.35 to 0.32, except for Marine in Climate Zone 4. In Climate Zones 5 to 8 (Ohio to Alaska) it was reduced from 0.32 to 0.30.

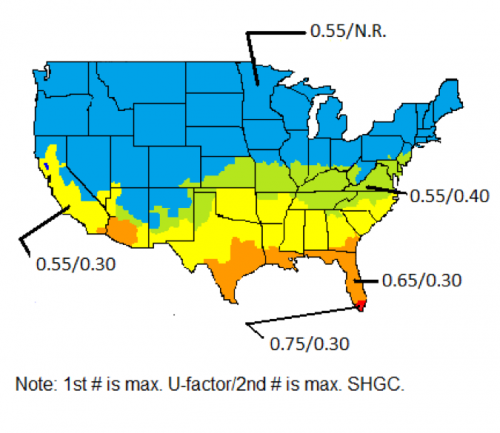

The maximum prescriptive SHGC and U-factor for skylights did not change between the 2015 and 2018 IECC.

Figures 1 and 2 show the maximum permitted U-factor and SHGC for vertical fenestration and skylights in low-rise residential construction when the prescriptive path of the 2018 IECC and 2018 IRC is used.

Figure 1 (below): Residential U-factor and SHGC for fenestration: prescriptive path of the 2018 IECC.

Figure 2 (below): Residential U-factor and SHGC for skylights: prescriptive path of the 2018 IECC.

The other three compliance paths for residential construction in the 2018 IECC permit some tradeoffs in levels of energy efficiency from one building component to another. One of these—designated the UA alternate method—only permits tradeoffs between different elements of the building envelope.

The whole building performance path permits tradeoffs between some components of the residence that impact energy use. The ability to trade off a more efficient mechanical system for other components of the building, however, is not included in the list of those permitted in the 2018 IECC. This change from previous editions removed a significant incentive for builders to install more efficient mechanical systems than what is currently required by federal law.

Beyond this, the amount of tradeoff that is permitted for fenestration when following the UA alternate method or whole building performance paths also continues to be capped in the 2018 IECC. The performance caps are as follows:

- In the Northern climate zones 6 to 8 (roughly corresponding with Wisconsin to Alaska), the U-factor is not to exceed 0.40.

- In mid-level climates zones 4 and 5 (Northern Tennessee to Southern Wisconsin), the U-factor is not to exceed 0.48.

- In Southern climate zones 1 to 3 (Southern Tennessee to the tip of Florida), there is no U-factor cap, but the SHGC is not to exceed 0.50.

- The U-factor of skylights in climate zones 4 to 8 is not to exceed 0.75.

- The same SHGC cap of 0.50 that applies to vertical fenestration in climate zones 1 to 3 also applies to skylights.

Exterior Glass Doors

The U-factor requirements discussed above for vertical fenestration also apply to exterior glass doors. Glass doors, by definition in the IECC, are considered to be those which are more than 50 percent glass in area. If the door is equal to or less than 50 percent glass, it is considered to be an opaque door. Although opaque doors are included in the definition of fenestration area in the 2018 IECC and 2018 IRC, they are assigned a maximum U-factor of 0.35, separate from the U-factor requirements for vertical fenestration.

According to Table R303.1.3(2) of the 2018 IECC, this criterion is considered to be met by any insulated, nonmetal edge opaque door with glazing less than 45 percent of the door area, when any glazing that does occur in the door is double pane. Also, one opaque door up to 24 square feet in area is exempt from the maximum U-factor requirement in the 2018 IECC (R402.3.4) and 2018 IRC.

The ERI Path

The Energy Rating Index (ERI) path that was added into the 2015 IECC did receive some changes in the 2018 IECC. The method for determining the ERI is now required to be in accordance with the RESNET/ICC Standard 301, which covers how to calculate the ERI score, compliance software tool certification and provides sources for input values not specified in the 2018 IECC.

In the 2018 IECC (Table R406.4), there was an increase in maximum ERI scores from 51-55 to 57-62. Specifically, ERI scores were increased from 55 to 61 in Climate Zone 5 and from 51 to 57 in Climate Zone 3. Where on-site renewable energy is included in the ERI calculation, buildings must meet or exceed the thermal envelope requirements in Table 402.1.2 of the 2015 IECC, but the 2009 IECC envelope backstop will remain in effect for buildings without on-site generation.

Air Leakage

The 2018 IECC and IRC require air leakage resistance of windows, door assemblies and unit skylights to be determined in accordance with AAMA/WDMA/CSA 101/I.S.2/A440 (NAFS)-17 or NFRC 400-17. This is similar to the requirements in the 2015 IECC and IRC, but the user should recognize that both standards were updated to 2017 editions in the 2018 IECC.

The pass/fail criterion for windows, skylights and sliding glass doors remains at 0.3 cfm per square foot. The pass/fail criterion for swinging doors remains at 0.5 cfm per square foot.

Replacement Windows

Both the 2018 IECC and IRC continue to require that replacement windows comply with the energy conservation requirements for fenestration in new construction. This requirement applies whether the entire window unit—including frame, sash and glazing—is being replaced, or just the sash and glazing.

Sunrooms

The 2018 IECC permits glazing in thermally isolated sunrooms to have a maximum U-factor of 0.45 in climate zones 2 to 8. By definition, a thermally isolated sunroom must be separated from the remainder of the building either by existing exterior wall construction or construction that meets the energy efficiency requirements of the 2018 IECC for exterior walls.

Thermally isolated sunrooms must also be equipped with a separate heating or cooling system or thermostatically controlled as a separate zone, if conditioned.

Under the 2018 IECC and IRC, sunrooms that are open to the rest of a building can be built as an addition, or part of new construction, but they must meet the same requirements for energy efficiency as the rest of the home. This can be accomplished using any of the compliance paths in the IRC or IECC.

Code Cycles

As noted at the outset, this article focuses on the requirements of the 2018 editions of the International Codes, specifically the IRC and IECC. Heading into 2019, it is anticipated that adoption of the 2015 IRC and IECC will continue to decrease, as jurisdictions begin their review process in consideration of adoption of the 2018 I-codes. Adoption and enforcement of a new edition of a model construction code traditionally occurs most significantly in the second and third years after its publication.

Some states specifically opted to skip the 2015 edition of the International Codes and continued to use the 2012 or earlier edition until the 2018 edition became available last year. It is anticipated that, in a similar fashion, the 2015 International Codes will continue to be used by some jurisdictions until at least 2021 or later. This is why it is imperative that the code user verify the edition of the code in any specific jurisdiction prior to beginning a project there.